AUTOCLAVE VERTICAL SLES SERIES | GET YOUR AUTOCLAVE PRICE HERE

Cominus Scientific is Introducing Your Trusted Sterilization Solution -

Cominus Scientific, is now on the way of becoming one of the Top-most Laboratory Equipment Manufacturing company in India. As Cominus provides custom products for their users without sacrificing the quality of the product. Our team is continuously working on the Designs and Manufacturing methods of the laboratory equipment, so we can get more connected to our users due to our quality.

Cominus Scientific is proud to present the Vertical Autoclave Economy

Series, designed to meet the stringent sterilization needs of laboratories, medical facilities, and research centres. Engineered with precision and reliability in mind, this autoclave series combines cutting-edge features, such as a PID controller-based microcontroller, a sliding lock mechanism, and optimal pressure and temperature settings. Let’s delve into the exceptional qualities that make this autoclave a standout choice.

Experience advanced sterilization technology with our Vertical Autoclave Economy Series, featuring microcontroller-based PID control. Designed to meet the demands of modern laboratories, this autoclave combines precise temperature control, efficient performance, and user-friendly operation.

As a trusted name in scientific equipment manufacturing, Cominus Scientific prioritizes product quality and customer satisfaction. The Vertical Autoclave Economy Series undergoes rigorous testing and adheres to industry standards, providing you with peace of mind and confidence in your sterilization processes. Our commitment to excellence is evident in every aspect of our autoclave’s design and performance. It is one of the finest product of Cominus Scientific. You can use it for different purposes like, educational, research, manufacturing, waste treatment and many more. This product of Cominus Scientific is an efficient product which fulfills all the requirement which is necessarily important for the sterilization. Our products are also energy efficient and that makes our product more efficient.

Special Features available in Autoclave of Cominus Scientific:-

- Efficient Sterilization Performance:-

With an operating pressure of 15 psi and an operating temperature range of 125 degrees Celsius, this Economy Series ensures efficient and thorough sterilization. This product effectively eliminates bacteria, viruses, and other microorganisms, providing a safe and sterile environment for your laboratory equipment, glassware, and media. Generally, these sterilizers are operated at 121 degrees Celsius of temperature and 15 PSI of pressure for 15-20 minutes for sterilization while with 135 degrees Celsius of temperature and 30 PSI of pressure, it takes 3-5 minutes for the sterilization. At Cominus Scientific, we have both type of Autoclaves.

- Secure Sliding Lock Mechanism:

Efficiency and convenience are paramount in any laboratory setting, which is why our product features a reliable sliding lock mechanism. This mechanism guarantees secure and tight sealing during the sterilization process, preventing any potential leaks and maintaining a controlled environment within the chamber. Through the duration of the sterilizing process, your samples are kept securely sealed. For your sterilizer, Cominus Scientific created a new opening and closing method. Our sliding lock mechanism was created in a way that combines security with an easy-to-open characteristic.

- Precise temperature control for accurate heating:

Cominus understands their responsibility towards their people, and we have make our product in such a way that it has precise temperature control which will provide that kind of accurate heating which is preferred by you and required for sterilization.

- Excellent temperature uniformity and stability which makes it more efficient to sterilize your equipment.

- Digital temperature display for easy monitoring.

- Programmable settings for automated temperature profiles.

- User-friendly control panel for easy operation.

- Durable construction for long-lasting performance.

- Safety features including over-temperature protection and door interlocks to make it more safer for you.

- Versatile and suitable for various applications in research, industry, waste treatment and scientific settings.

- We also make HMI based Autoclave machines to make it more user-friendly and easy to use product.

- Customization at Cominus Scientific is also available so, you can customize your product as per your requiremnet.

- User-Friendly Interface:

This product features a simple control panel that was made with user convenience in mind. The simple interface and clear display make it simple to configure and keep track of sterilization cycles. The simple buttons make adjusting temperature, pressure, and cycle length simple, allowing you to streamline your process and increase productivity.

Product Specifications:-

| MODEL NO | CM-VAV-SLES-50 | CM-VAV-SLES-90 | CM-VAV-SLES-150 | CM-VAV-SLES-200 | CM-VAV-SLES-3012 | |||

|---|---|---|---|---|---|---|---|---|

| Capacity (Liters) | 50 | 90 | 150 | 200 | 120 | |||

| Operating Temperature (°C) | 100 - 125 (°C) | Up-to 135 °C | ||||||

| Operating Pressure (PSI) | 15 PSI | Up-to 30 PSI | ||||||

| Lock Mechanism | Sliding Lock | Sliding Lock | ||||||

| Control Sytem | Microcontroller based PID Control | Programmable Logic Controller with 4 temperature channels and 1 inbuilt pressure channel based Touch HMI Display | ||||||

| Heating System | Efficient and rapid heating system. | Efficient and rapid heating system. | ||||||

| Chamber Construction | AISI 304 | AISI 304 | ||||||

| Chamber Dimensions | Ø350 x 500 | Ø450 x 600 | Ø550 x 700 | Ø650 x 750 | Ø450 x 750 | |||

| Power | 220 V / 50 Hz | 220 V / 50 Hz | ||||||

| Warranty | 1 Year | 1 Year | ||||||

What is autoclave and its functions?

It is an equipment which is used for the sterilization of the equipment used for scientific research, manufacturing of pharmaceutical products, surgical instruments used by the doctors during surgery. They combine steam, pressure, and time to operate. It uses high pressure and warmth to kill spores and germs. In microbiology and mycology, medicine and the manufacture of prostheses, tattooing and body piercing, and burial rituals, sterilization autoclaves are frequently employed. In the chemical and food industries, they are sometimes referred to as retorts and vary in size and purpose depending on the media to be sterilized.

These are generally being used at 121 Degrees Celsius of temperature with 15 PSI of pressure which takes around 30-60 minutes to reach the stage of sterility. and 135 Degrees Celsius with 30 PSI of pressure which takes 3-4 minutes for the sterility stage of the medical instruments or lab equipment. These are also frequently used to cure composite materials, particularly when joining many layers without creating cavities that would reduce the strength of the material, and when vulcanizing rubber. The best repeatable physical qualities are made possible by the intense heat and pressure that it produce.

It is used to sterilize lab equipment, sterilize media, and decontaminate specific biological waste. Before disposal, it is advised to sterilize regulated medical waste that may contain bacteria, viruses, and other biological material.

Research-Grade Sterilizers: –

In these situations, when effectiveness, usability, and adaptability are crucial, research-grade autoclaves are being employed more often. It is possible to set up research-grade autoclaves for “pass-through” operation. This enables complete separation between “clean” and possibly polluted work areas to be maintained. In BSL-3 or BSL-4 facilities, pass-through research autoclaves are very crucial.

Research-grade sterilizers are primarily made for effectiveness, adaptability, and user-friendliness; they are not certified for use in sterilizing equipment that will be used on people. They come in a variety of shapes and sizes and are typically customized for each usage and load type. Common variants include a square or cylindrical pressure chamber, water- or air-cooling systems, and doors that open either vertically or horizontally and can be propelled by either electricity or physical effort.

Many medical facilities, labs, and other locations that need to guarantee an object’s sterility, use autoclaves. Nowadays, single-use materials are used in many operations rather than sterile, reusable ones. It started with hypodermic needles, but nowadays many surgical equipment (including forceps, needle holders, and scalpel handles) are often single-use products rather than reusable ones (see waste autoclave). Due of the vastly increased volume of repurposed equipment in underdeveloped nations, this product play a particularly important role in these environments. Several planned medical assistance missions have included the delivery of solar or stovetop type to remote medical facilities.

What is the principle of Autoclave:-

The physical process of disinfection and sterilizing is provided by autoclaves. They combine steam, pressure, and time to operate. Autoclaves use high pressure and warmth to kill spores and germs.

They are used to sterilize lab equipment, sterilize media, and decontaminate specific biological waste. Before disposal, it is advised to autoclave regulated medical waste that may contain bacteria, viruses, and other biological material.

What are the compatible materials for the autoclave?

- Tissue Culture Flasks.

- Surgical Instruments.

- Glassware.

- Pipette Tips.

- Media Solutions.

- Animal Food and Bedding.

- Waste.

- Polypropylene (Secondary Containers).

- Stainless Steel.

- Gloves.

What are the types of autoclave?

There are two different types of autoclaves that are being used in the industry: –

- Gravity Autoclave – The most common and affordable options are gravity autoclaves, also referred to as gravity displacement autoclaves. Steel utensils, glassware, and biohazardous waste are among the regularly used laboratory media that they are appropriate for sterilizing. The idea behind gravity-induced autoclaving is to force ambient air out of the autoclave’s chamber through the exhaust valves by pouring steam into the chamber. By doing this, the leftover steam can effectively sanitize the contents. These autoclaves are suitable for sterilizing of non-porous items such as SS surgical instruments and utensils which are used in the laboratories, biohazard waste, polypropylene pyrex or type I borosilicate glassware, unwrapped goods.

- Vacuum Autoclave – Vacuum autoclaves, often referred to as pre-vacuum autoclaves, are excellent in instances when air removal is difficult. They work well for sterilizing bulky or porous things like animal cages, bedding, and surgical supplies that have been wrapped. These autoclaves’ suction feature guarantees a more complete sterilizing procedure. High-temperature steam may enter and sterilize spaces that would otherwise be inhabited by air by removing the ambient air from the chamber. Sterilizing items with difficult-to-reach locations is made very effective using this method. These autoclaves are suitable for sterilizing large & porous items such as, animal cages and bedding, wrapped dry items that can trap air, media solutions in containers, like tissue culture flasks with loose caps, high density polyethylene products, such as pipette tips and syringes.

YOU MIGHT ALSO BE INTERESTED IN

Our team is working hard day-by-day to deliver the quality product to our customers. Besides this we also have ‘Stability Chamber’, ‘Hot Air Oven’, ‘Plant Growth Chamber’, ‘Water Bath’, ‘Horizontal Laminar Air Flow’, ‘Vertical Laminar Air Flow’, ‘Tissue Culture Lab Setup’, ‘Laboratory Furniture’, ‘Custom Design’, ‘Ethyle Oxide Chamber’, ‘Mini Incubator’, ‘Vacuum Oven’, ‘Acrylic Vacuum Chamber’, ‘PCR Cabinet’, ‘Grossing Station’.

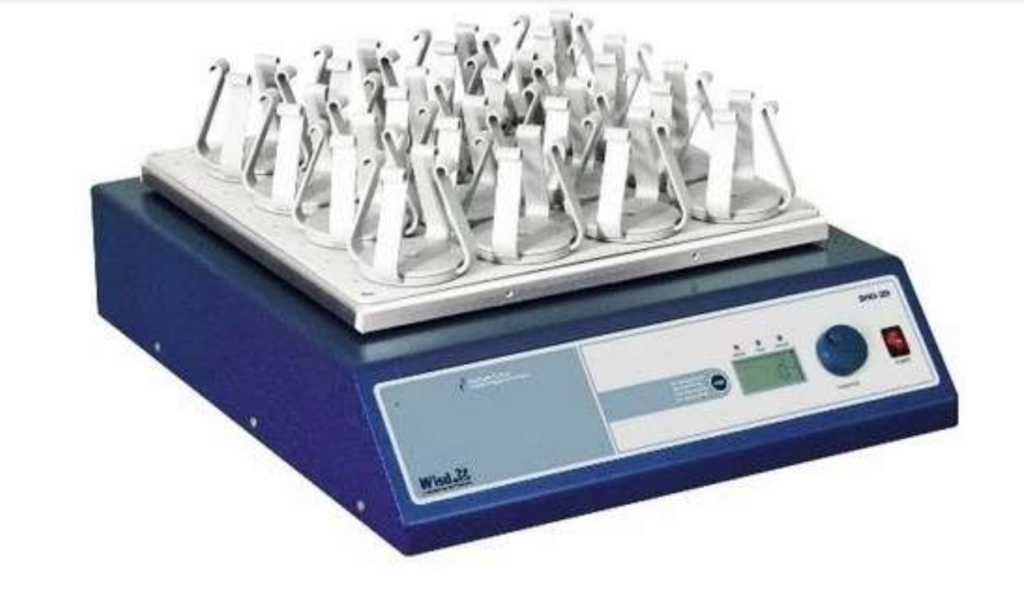

Incubator Shaker

Orbital Shaker

Our bench-top orbital shakers are made to produce uniform mixing for productive cultivations.

ACRYLIC VACUUM CHAMBER

We are pleased to introduce to you our solidly constructed and well-made acrylic vacuum chambers.