AUTOCLAVE | COUNTER PRESSURE AUTOCLAVE

Introducing the Counter Pressure Autoclave

Cominus Scientific makes counter pressure autoclave for research work. We are the most trustworthy and reputable manufacturers of steam air/water counter pressure autoclave. We work hard to deliver high-quality responses with comparable performance par excellence for our customers at the lowest possible price.

One of the most effective methods for the conservation of perishable food is sterilization by direct application of moist heat, which is done on food packed in hermetically sealed containers. This method eliminates the pathogenic microorganisms that are dangerous for the consumer; It also eliminates

those that alter the food in storage and distribution conditions. We must appropriately control the thermal treatments in order to exceed the lethality limits of the pathogenic microorganisms. This will ensure the food safety and its commercial sterility. This is possible by applying a risk management system, based on the methodology of hazard analysis and critical control points;

Therefore, it is important to highlight the enormous importance of having the right equipment and the right conditions to achieve the perfect execution, reproducibility and control of thermal processes. Cominus stands out for its excellence in the control and reproduction of thermal processes, while

maintaining the perfect balance between these factors.

Cooking Sequence of autoclave:-

- Venting Period

It is important to get the air out of the retort before the cooking period starts because air, due to poor heat conductivity, acts as an insulator preventing the canned product from being adequately cooked. Proper venting is achieved by purging for a pre-set time period and to a desired temperature.

- Raise-to-autoclave temperature

This period occurs after the completed vent period and is the interim period from the vent temperature to cook temperature.

- The Autoclave Period

This period is essential in order to cook the product thoroughly, thereby destroying any organisms that could later spoil it. These organisms, called spores, are able to withstand several hours of atmospheric boiling water temperature, but are destroyed in a short time at a temperature of 116 to 121°C (240 to 250°F).

- Blowdown Period With maintain Chamber Pressure

The reduction of internal can pressure is obtained by circulating cooling water through the retort whilst maintaining retort pressure at the value attained during cooking by introducing pressurizing air. When can internal pressure has dropped to a safe value, indicated by the temperature of the cooling water leaving the retort dropping to a desired value, blowdown can take place without the threat of can damage.

Special Features:-

- Automatic temperature control.

- Up to twenty set point profiles, including guaranteed ramp and soak with individual hysteresis for precise temperature profiles and improved product quality.

- The large, easy-to-read front panel display.

- Fully programmable using PC Configuration software.

- Fast startup with self-seeking set point.

Product Specifications:-

| MODEL NO | CM-CPVAV-50 | |

|---|---|---|

| Control System | PID Microcontroller | |

| Display | LCD | |

| Internal Chamber Volume | Ltrs | 50 |

| Chamber Type | Vertical | |

| Door Opening Mechanism | Sliding | |

| Operating Temperature | ℃ | 100-125 |

| Operating Pressure | PSIG | 15 |

| Castor Wheel | Yes | |

| Operation | Fully Automatic | |

| Power | 220 V AC 50 Hz | |

| Warranty | 1 Year |

Additional required accessories:-

- Air Compressor

Site Utility Requirement:-

- Site Utility Requirement.

- Water Source Point.

- Water Drain Point.

YOU MIGHT ALSO BE INTERESTED IN

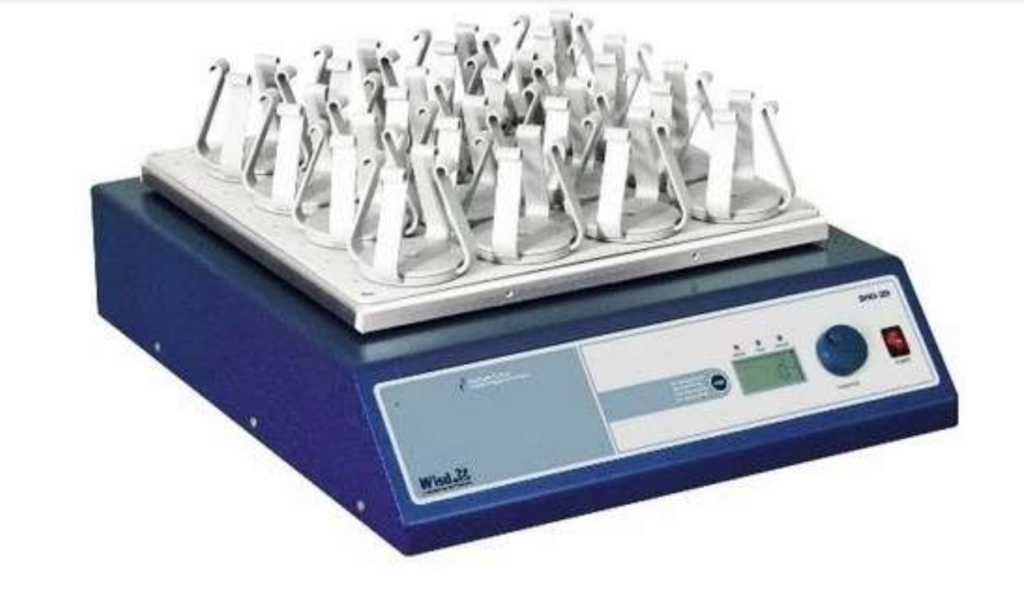

Incubator Shaker

Orbital Shaker

Our bench-top orbital shakers are made to produce uniform mixing for productive cultivations.

Plant Growth Chamber

It can be used for a variety of purposes, including quality assurance testing, durability testing, and reliability testing.